Ann asked some questions about my sweater, and I figured I’d answer in a new post

I’m curious about whether you had any problems with your yarn getting sucked down into the bobbin area in your sewing machine as you stitched. The proprietor of our local yarn shop told me that that is her greatest worry about steeking – not the cutting, but the stitching – and we discussed the wisdom of basting some tracing paper to the back side of the sweater to prevent that problem. Or did you stitch with the wrong side of the sweater up?

I was nervous about problems when doing the sewing, but it went much more smoothly than I’d feared. The hardest part of the process was remembering to breathe while stitching the seams. I did the seaming with the right side of the sweater up and had no problems with yarn getting caught in the feed dogs or sucked down into the bobbin area. I used a stitch length of 2 (I’m not sure what the units of stitch length measurement are – millimeters, maybe?). The major change from my usual sewing was to use a different presser foot. According to my sewing machine manual, it is the Satin Stitch Foot. Most of the foot is clear plastic, and there is a handy arrow pointing toward where the needle is, so that helped immensely in “aiming” exactly where I wanted to sew into the needle. There’s probably some technique for taking good pictures of small, transparent plastic things, but I don’t know it, so here’s my best shot:

I do admire your persistence in redoing your sleeves to get them to fit just right, but why did you cut off (aaaaaagh!!!) the top of the sleeve before redoing it rather than unravelling it?

I had a couple of reasons –

1. I put a bunch of effort into those sleeve tops, and I figured I could re-make the sleeve tops into hats or something else useful.

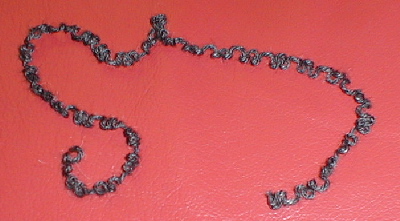

2. I’d already blocked the sleeves, so the unravelled yarn was really, really crinkly and would’ve require re-conditioning to be knittable. I had plenty of extra gray yarn, and bought more off-white yarn (which is a good thing, because I had to use some of the new skein to finish off the body knitting). This picture doesn’t fully convey the 3-dimensional crinkliness, but you can get an idea:

To avoid disaster when cutting off the sleeves, I ran smooth cotton yarn through the row of stitches where I wanted to begin knitting again, then skipped three rows of knitting, and ran another length of yarn through an entire row. I cut through the middle of those three skipped rows, then was able to put the yarn-held row of stitches onto a circular needle, unravel the row above it, splice in the new yarn, adn begin knitting again. On my sleeve comparison, you can see the yellow “holding” yarn on the sleeve top.

And call me old fashioned, but I really don’t understand why anyone would choose to “cardiganize” a sweater. If you want a cardigan, why not just knit one?? I guess it’s just a Scandinavian thing.

The sweater pattern is for a cardigan – it’s just the Norwegian style to knit the sweater in a big tube with extra cutting stitches in the middle front, and then steek it.

And now, off to work on picking up stitches for the neckband!